Find Wafer Butterfly Valve, High Quality Wafer Butterfly Valve, Wafer Butterfly Valve Details on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

Model No.: JBFSBV-119

Multiple materails selection

Long service life

Low pressure loss

Perfect appearance

Product Overview

The fire signal Butterfly valve and normal signal butterfly valve we developed, has successfully past the examination of public security inspection center. The product has high performance, reliability, and long service life, special for high rise construction fire control system. Has widely used in the field of petrochemical, medical, food, water supply, metallurgy, energy and Other system which needed display of switching situation and output signal. adapted for various of mediums conclude gas, liquid, powder, to adjust or stop the flow.

Products features

1. The fire signal butterfly valve conform to GB5135.6-2003, the inspection of seal, strength, performance is far above test for normal valve, to guarantee the reliability of product.

2. Adopting no-pin connection technology, reliable and long service life, keep long term zero leakage; coaxial type structure, eliminate the impaction of cumulative error, accurately reflect the on/off state of valve, the product can output two geometric position signal.

3. Use several of materials like nylon, PTFE, corrosion resistant alloy, can satisfy different of requirements of mediums.

4. Use proxy resin coatings, good appearance, and high corrosion resistance. Electrical switch box is whole sealing structure, all connecting areas set seal washer, therefore, totally suitable for indoor/outdoor.

5. Valve and signal device are qualified before delivery, customer could use it directly after installation according to circuit diagram.

Operating principle

Rotate hand wheel drive worm gear and stem, to switch and adjust the disc.

Transmission device set two jogging switch, take motions at the fully opening or closing state, the signal device will connect the local and remote control room automatically.

Name | Fire Signal Butterfly Valve | General Signal Butterfly Valve | |||

Connection | Wafer | Lug | Wafer | Lug | |

Nominal diameter | DN40~DN200 | DN50~DN200 | DN40~DN350 | DN50~DN350 | |

Nominal Pressure | 1.2MPa | 1.0MPa | 1.6MPa | ||

Housing Test | 4.8MPa | 1.5MPa | 2.4MPa | ||

Seal Pressure | 2.4MPa | 1.1MPa | 1.76MPa | ||

| Applicable Mediums | Fresh Water | Water, Salt, Acid, Alkali, Nature gas, Air, Alcohols, oils, food, steam and so on. | |||

Medium Temperature | 0~95°C | -30~180°C | |||

Environment Temperature | -10~55°C | ||||

Surface Treatment | Red Epoxy Coating | ||||

Driven Type | Worm Gear Reducer+coaxial switch signal feedback device | ||||

Load Capacity | 24mA | ||||

| Withstand voltage capacity | 1000V | ||||

Insulation resistance | Test voltage = 500V±50V, Insulation resistance>50MΩ | ||||

Contact resistance | <0.015Ω | ||||

Optional materials for parts

Name | Optional Materials |

Body | Ductile Iron(DI), Gray Cast iron(CI), Cast Steel(WCB) |

Disc | Ductile iron nylon coating(N),Plated ductile iron(D), CF8(P), CF8M(R),Aluminum bronze(T) |

Seat | EPDM , NBR. PTFE, VITON, EP, EPDM ,EPDM |

Shaft | 416SS 316SS 304SS CS45#coating with Ni,P |

| Actuator | Worm Gear Reducer+coaxial switch signal feedback device |

Matters need attention for installation

1. Pipeline wafer type flange standard should be in accordance with the standard of butterfly valve, dedicated flange of butterfly valve is recommended for wafer type connection flange.

2. Users should check the working conditions if it is accordance with the butterfly valve.

3. Lumen and sealing surface should be cleared up before installation, no waste adhering.

4. Both side of valve seat extruded as seal washer of flange, no need to use seal washer for butterfly valve

5. The butterfly valve could be installed at horizontal, vertical and any other angles of pipelines, and could be used in two-way.

6. The butterfly valve can not be installed at the corners of pipeline, no handstand installation allowed.

7. The butterfly valve must be closed when installing, to assure valve plate not to impact with the pipeline flange.

8. Verify flange welded without defects. Can not weld after installation to avoid to scald rubber articles and antiseptic coatings.

9. For abnormal situations on switching, should check it out, remove faults, do not open or close the valve with external force.

Features & Benefits

•Packaged in pallet box containers or on pallets, adequately protected for shipment.

•Each valve is individually tested.

•Various materials and services available to meet your unique requirement.

THT provides:

•Sample order. Shipping way as you required: by sea/air/express.

•Professional assistance. Our engineers can assist you in making the right choice of valve for your application.

•Quality control. THT is committed to a philosophy of total quality management. THT valves are compliance with relevant GB and ASME standard (other standard can be provided as well), tested before shipment.

Please feel free to contact us for other types of valves, valve spare parts, flanges & strainers, etc.

About us

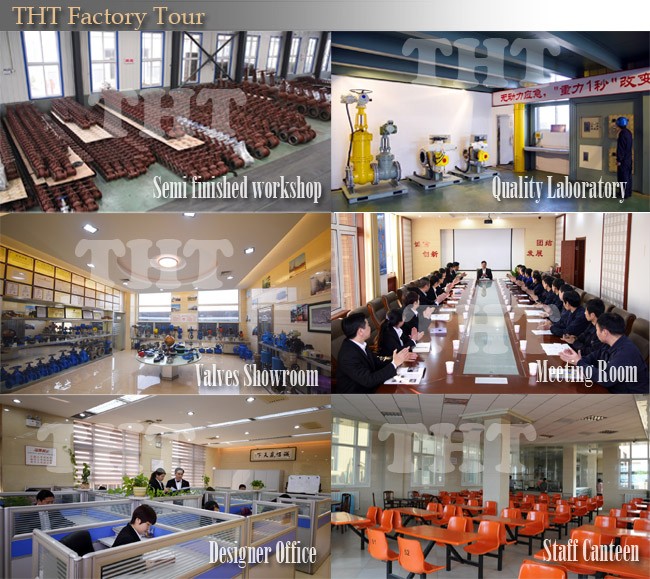

THT Valve, one of the largest manufacturing factories in Tianjin, China, is committed and dedicated to provide quality, on-time products. For all your valves, valve parts and strainers, contact us at THT Valve. We pride ourselves on our knowledge, our service, our products, our industry certifications, and look forward to partnering with you to supply all your valve product requirements.

Contact us if you need more details on Fire Fighting Signal Butterfly Valve. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wafer butterfly valve Butterfly Valve、Awwa C504 Wafer Butterfly Valve. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Butterfly valve > Wafer butterfly valve